Intuitive-Control Gurney

Med-Tech Project; Year: 2016 ; Time spent: 3 weeks; Budget: $150

Two-person team; My Role: Ideated and led the build of the project, Designed the novel force-sensing mechanism, Integrated the electronics, Programmed the entire system

Built in a low-resource makerspace, primarily using handheld power tools, without 3D printing or machining equipment. Due to a short timeline, I did not even plan out the design on CAD. While I might approach this project quite differently now, I'm very proud of what I built given the resource constraints as a college student in India.

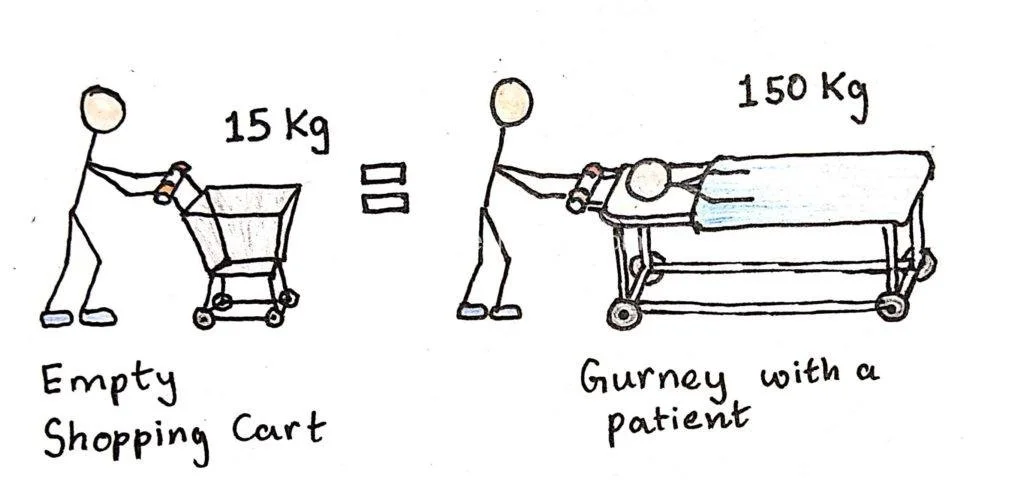

Feels just like pushing an empty shopping cart.

A prototype of an electric hospital gurney that anyone can easily maneuver without any training, similar to pushing an empty shopping cart. It interprets the user's intuitive movements by sensing the force applied to its handles and uses omni-directional mecanum wheels to move accordingly.

The Need: This intuitive-control gurney helps prevent accidents caused by a lack of manpower during patient transportation, especially when handled by untrained people, which is a common problem in many situations.

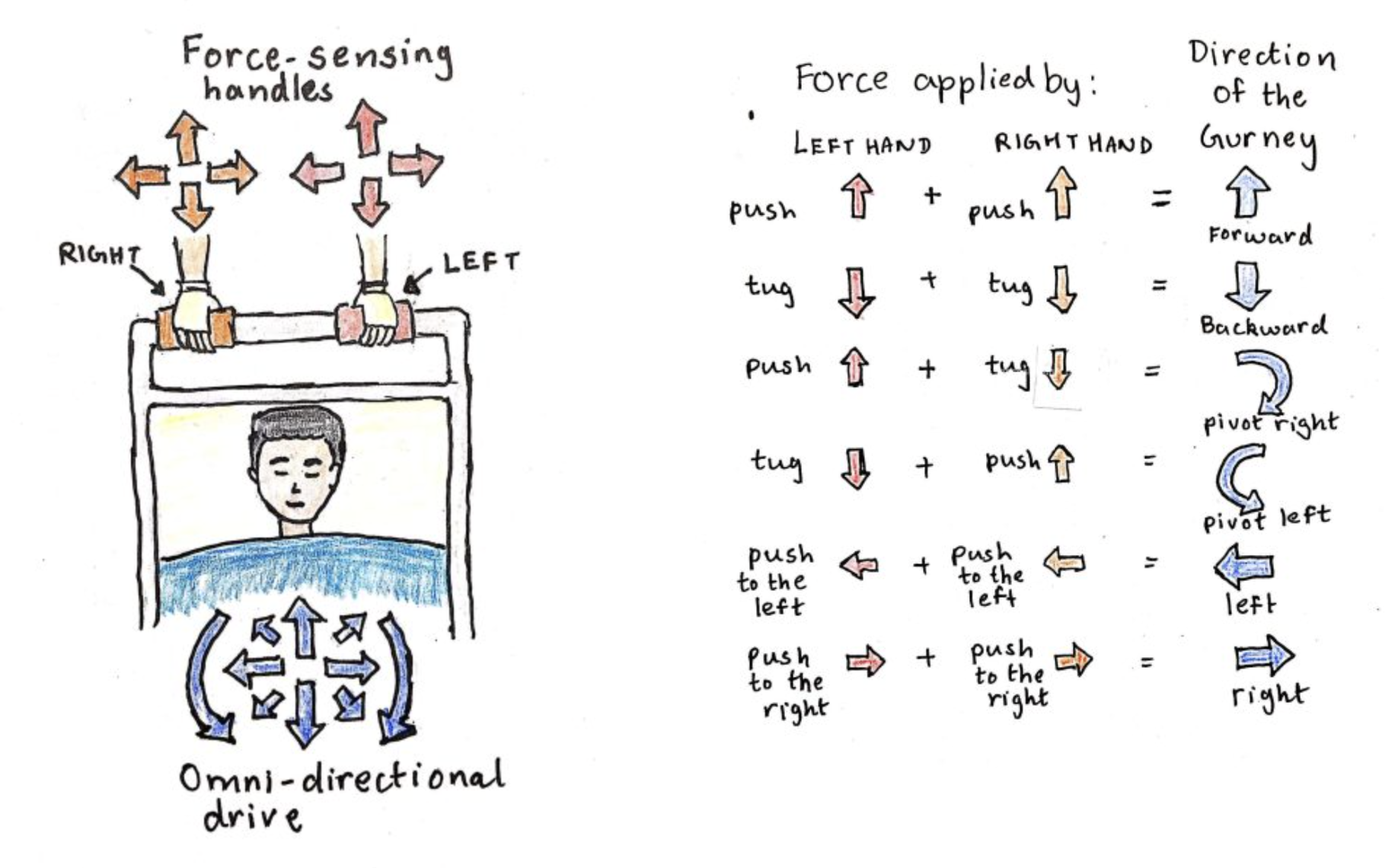

Operation:

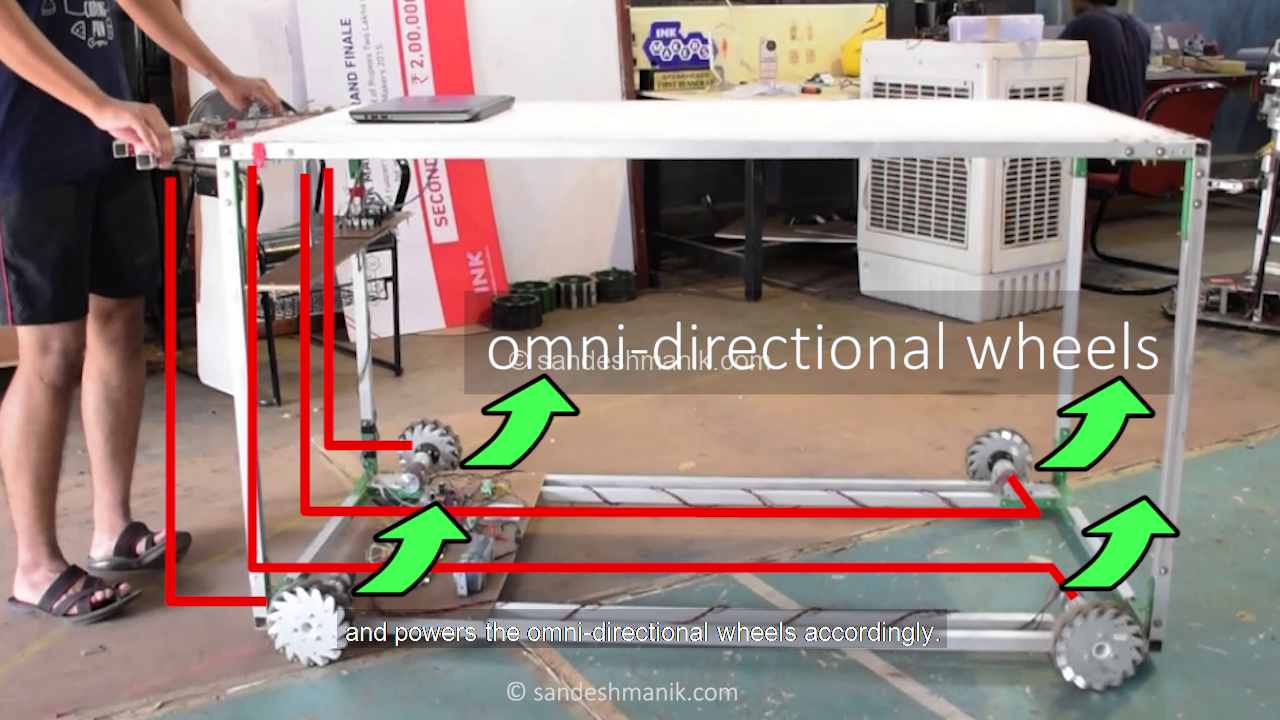

Just like a regular shopping cart on caster wheels, the gurney’s handles can be pushed or pulled with each hand independently in the forward and backward directions. Both hands can also tug the handle sideways together.

For example, Pushing with the right hand while tugging with the left means that the operator wants to pivot the gurney to the left; the harder they push and tug, the faster they wants to pivot.

The Technology:

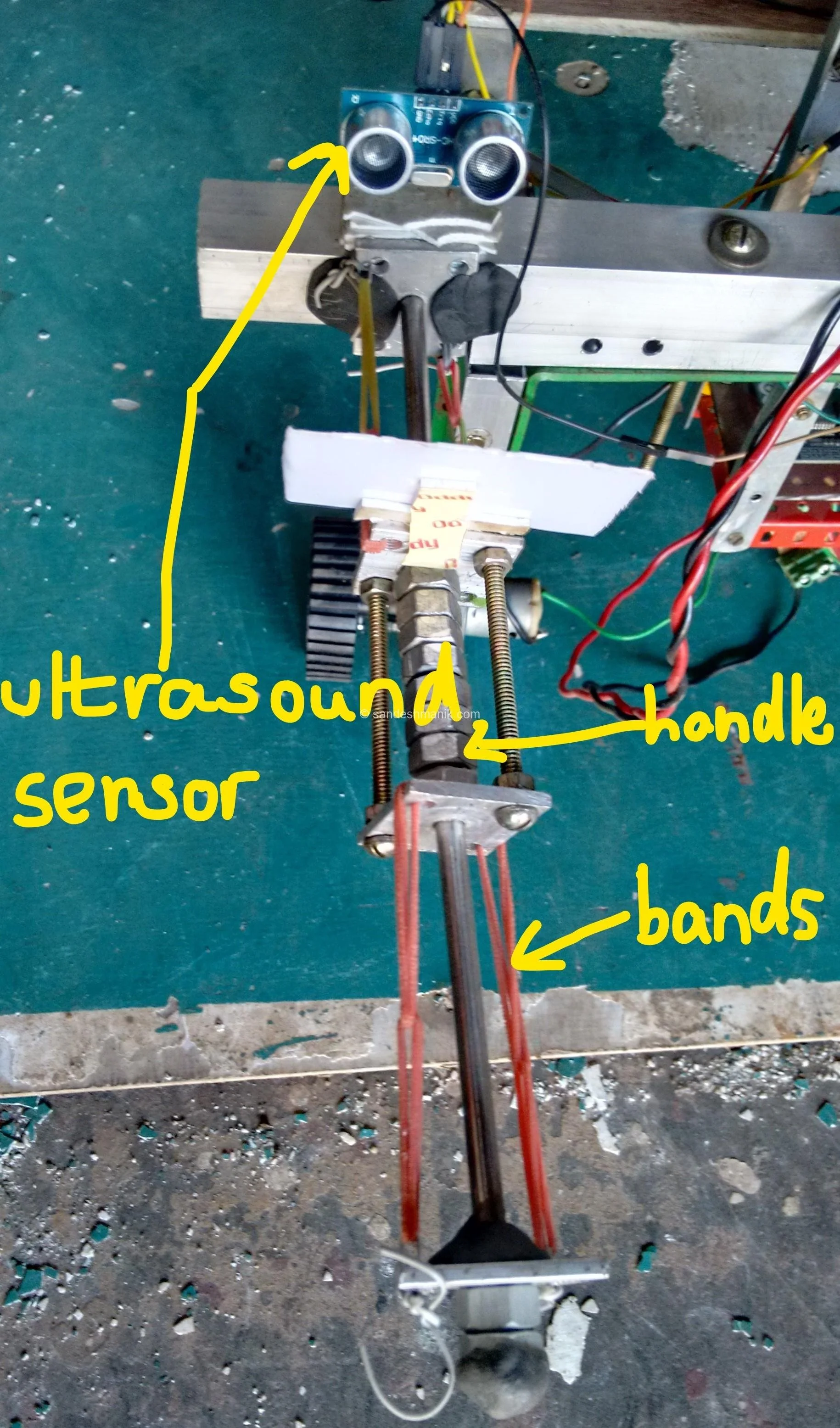

Sensing :

The handles measure forward and backward forces from each hand separately. However, it measures side-to-side forces from both hands together as one combined force, because it doesn't make sense for one hand to pull to the left while the other pulls to the right at the same time.

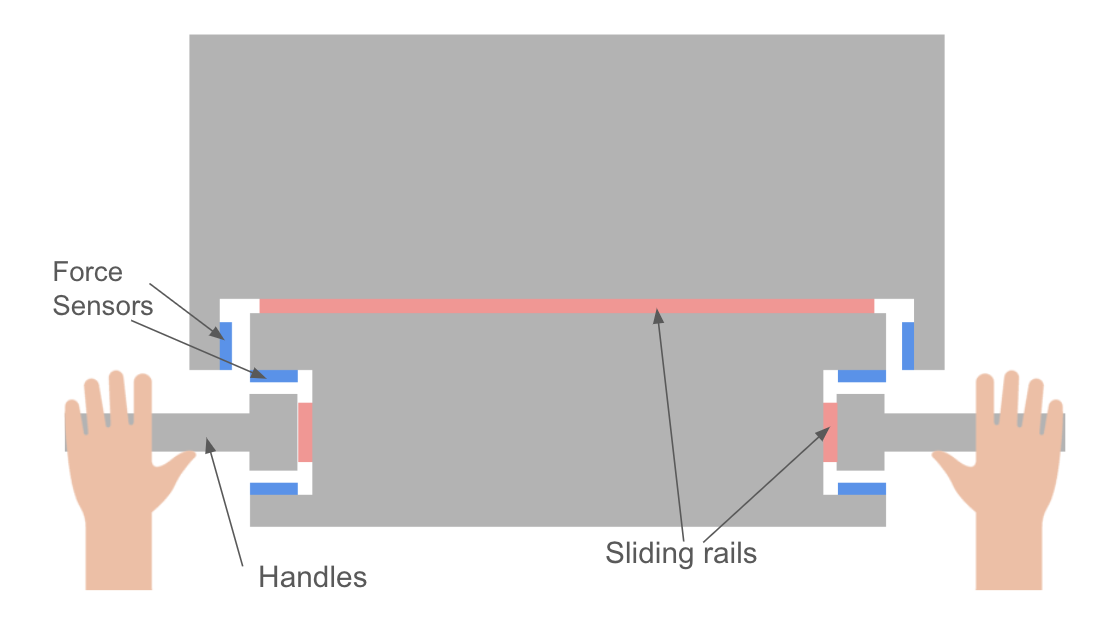

Force Sensing Mechanism: The handles have built-in piezoelectric force sensors that measure how much force is applied and in which direction. These sensors can only detect pushing forces, not pulling. Hence, to measure force in both directions along each axis, there are two sensors placed at opposite ends. This setup allows the device to accurately measure force no matter which way it's applied to the handles.

Sliding Rails: Mechanically, the handles are mounted on sliders so that force application on the sensor is precise and uniform everytime, and there is no cross-talk on opposite mounted sensors for a specific axis.

Force Sensing Mechanism

The application of force by two hands on the 6 force sensors.

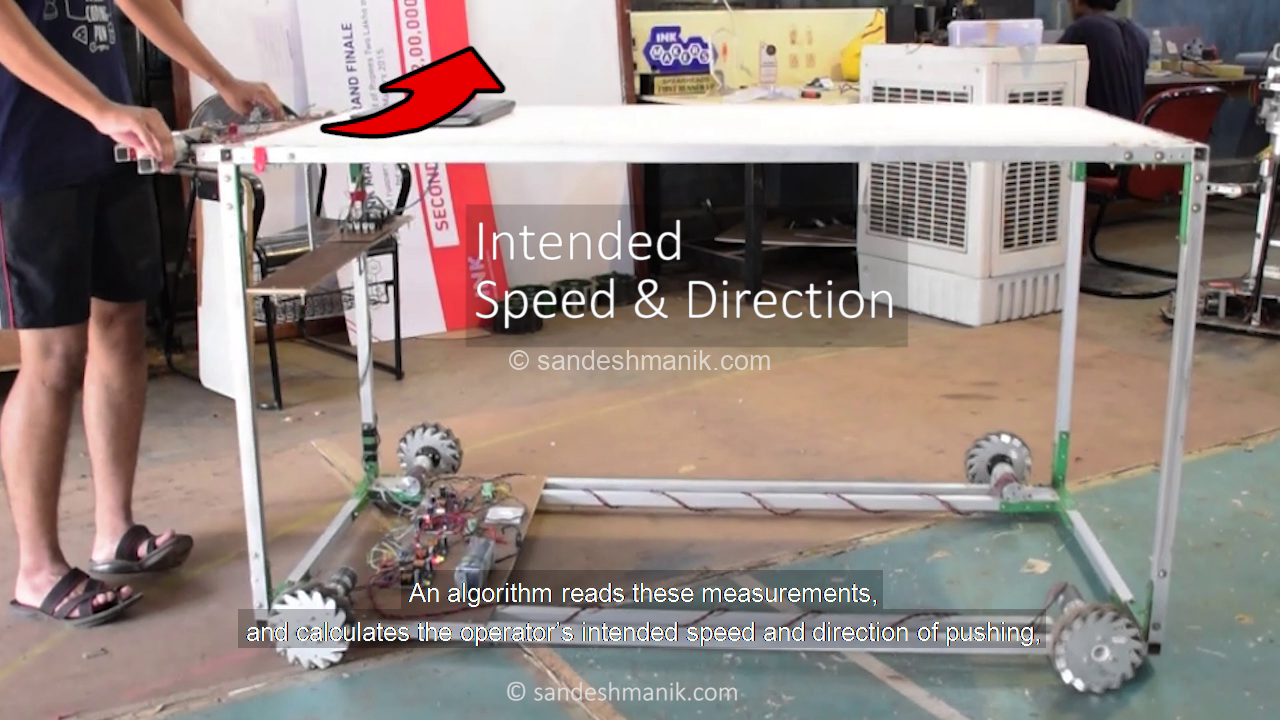

Controls:

Input: An Arduino microcontroller continuously reads the force sensor values.

Processing: The Arduino uses a PID (Proportional-Integral-Derivative) algorithm to smooth out the output values. This ensures that any jittery input doesn't cause unstable output.

Output: The Arduino sends PWM (Pulse Width Modulation) signals to the individual motor drivers, which then turn the wheels as required.

Actuation:

Omni-directional Drive: The omni-directional mecanum wheels allow the gurney to move in all four directions (forward, backward, left, and right) and rotate simultaneously. This mobility is similar to that of a regular stretcher with caster wheels.

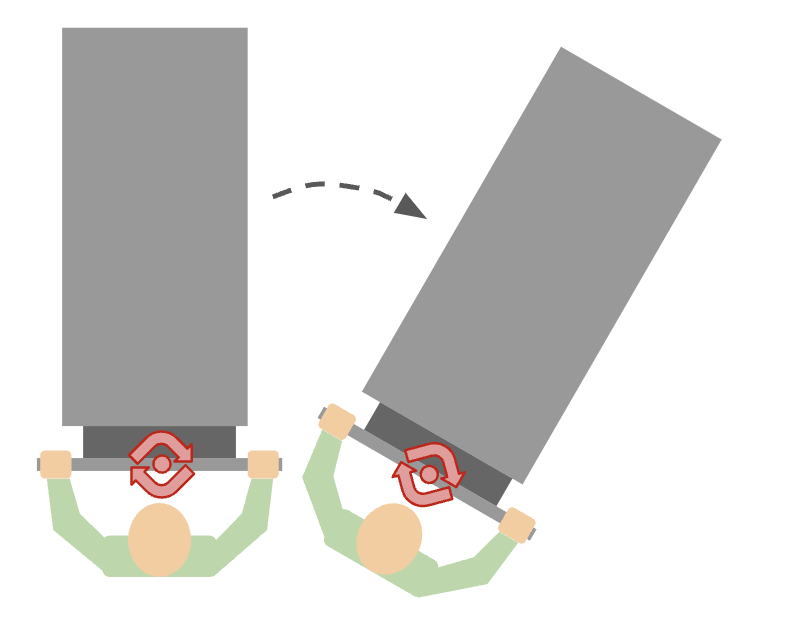

Rotation about the center of the handle is intuitive.

Intuitive Control: While the wheels are powered at their hubs, the movements are programmed to feel as if the power is coming from the operator's hands. This makes the gurney more intuitive to control.

For example, during a rotational turn, the gurney pivots around an axis that passes through the handle, rather than rotating around its center. This gives the operator the feeling that the power is being generated at their hands.

Scrapbook:

Assembling the Force Sensing Mechanism, way past bedtime…

An earlier prototype

Explaining the earlier prototype to Josh Radnor?!

Winning a cheque in a tech competition!